October 2, 2005

Today's project was to make a door buck that would hold both windows and doors for planing. The door bucks that I've seen use two triangular braces fastened to a thin piece of plywood. The weight of the door causes the plywood to bow and the triangles to pinch inward on the door, holding it upright. But, this wouldn't work very well on windows where glass or fragile muntins could be broken by the pinching. So William and I made a variation, using only materials found in dumpsters. All of the wood was scrap from our dumpster. In fact, we only had to make one saw cut, everything else was used as-found. Scrap rafter ends became our triangular braces. Attached to the braces are pieces of OSB so that the door or window is braced over a large area, eliminating the chance of damage to windows. On one side the braces are attached to the base with screws. On the other side bolts in the bottom of the braces travel in slots cut in the base so that they can spread from 1" to 2". Wingnuts underneath tighten that side down once it's been pushed into place against the door or window. For further protection, the inside faces of the OSB panels are covered with carpet harvested from a dumpster behind the local flooring shop. This new helper will be seeing a lot of use in the coming months as I work on countless doors and windows. I used one of our sacrificial window sashes to try out the buck and my new Delta Power Planer and they both worked great! October 4, 2005

Things are progressing with the framing, but the daily changes aren't as dramatic as they once were. The "ooh ah!" factor has diminished some. There are two still roof sections remaining to be built...over the colonnade and over the upstairs screened porch. They have started framing the roof extending the back porch to the new kitchen. October 5, 2005

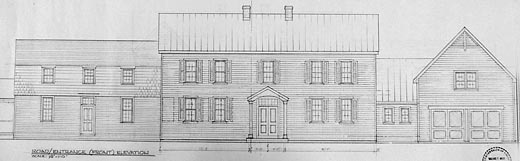

With all of the trees in the front yard, it's kind of hard to get a good view of the roadside elevation. But in this photo I think you can start to see how things are coming together. October 8, 2005

We have been so fortunate to have dry weather ever since framing began, with only the occasional nighttime shower. Today, however, it is pouring.

Much of the addition is under felt paper, but water is flowing in from the areas that aren't. Oh well, we could have seen a lot more of this along the way. It'll dry out.

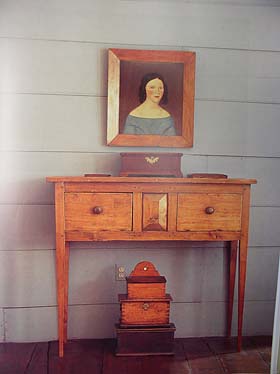

Confined indoors, we turned our attention to planning some finish details. For instance, we have been discussing using horizontal beaded, shiplap paneling in the family room. The boards will be mixed widths like this photo from "Creating A New Old House" by Russell Versaci.

It's interesting the some of the boards in the wall above are beaded and others aren't.

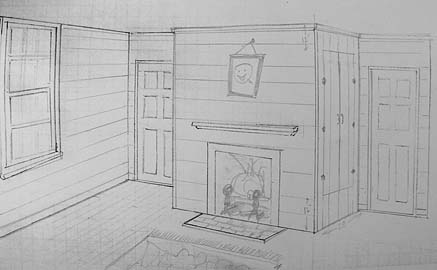

I'm thinking that on the return walls I will switch to vertical boards so that the doors can blend into that wall. I think the transition will work well and add to the old feel. October 10, 2005

Boy did we get rain this weekend! It was standing in several areas of the addition and made me very thankful that we used the Advantech subfloor. I have heard of it being under water for weeks at a time with no damage. It rained more today and still more is being forecast through Wednesday. I guess we're due.

The mason got going on the family room fire box today. The opening on this fireplace is 43" wide and 36" tall with a 20" deep hearth. I had no luck finding fire brick that looked remotely old, so we have opted to parge the new fireplaces instead. This will help them to feel older. I will create the hearth out of salvaged bricks from around the property. These will be set in a shallow bed of sand so that they can be leveled up with the firebrick inside the box. -- Bill

October 11, 2005

Today Gay and I ordered this light fixture for the new center hall. It's our 15th Anniversary gift to each other. -- Bill

October 13, 2005

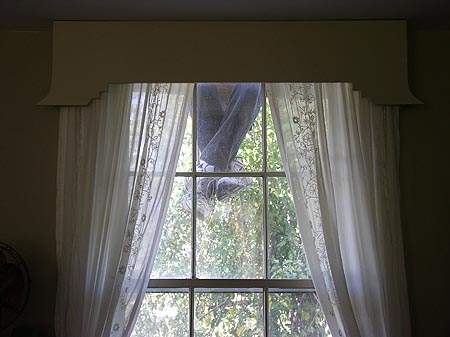

I wish I had a photo of our 15th anniversary dinner. If I did you would see a lovely table (set for three), candlelight, 2 and 1/16 glasses of Cabernet Sauvignon, and the three of us raising our glasses in a toast before enjoying a wonderful meal together. Just beyond the table you would see a window. And out the window, in the waning sunlight, you would see (and hear) our mason cutting through a tile flue with a diamond bit saw, stirring up a cloud of dust. How romantic... October 16, 2005

After a solid week of drizzle, the beautiful weather this weekend left us giddy and we happily took on some outdoor projects.

Even frustration with the finish quality of our Jeld-Wen windows couldn't dampen our spirits. (Out of 15 windows, only one miter joint wasn't spread wide open. See the forum for photo and comments.) Instead, I went to work sinking nails, filling holes and joints and priming the casing. Once done, the windows looked really good.

The windows in the kitchen are casements. I've never lived anywhere with casement windows and think we're really going to like these.

These old sawhorses, inherited from the previous owner, are backbreakingly low. So I made a new pair out of dumpster-salvaged parts. Turns out, engineered joists make great sawhorses! William tested them out...repeatedly.

Looks like the framers should be done by the end of the month. Then we can get going with siding!

I'm having to rethink my siding choice. My intent was to use 1 X 8 flat cedar boards with a 6" exposure. But the casing on the Jeld-Wen windows isn't deep enough for this. We'll need to go with a beveled siding instead. So tomorrow I'll be shopping for quartersawn Western Red Cedar.

October 20, 2005

This week has been quiet. The framing crew hasn't been here since last Friday. They were supposed to be back today, but didn't turn up.

I have started setting up the room above the garage as a temporary workshop. It's not great that it's upstairs, but I figure that we will be needing the garage itself for deliveries. Like our kitchen cabinets which are going to be here in about 3 weeks. (Yikes!) The electrician is going to run a temporary line to this room from the existing panel. At least it will be easy to pass long boards up there as long as the interior walls are just studs. October 26, 2005

Some days the advances are more visible than others. Today was one of those fun highly-visible-change days.

The front porch framing moved pretty quickly except for its barrel vault ceiling, which took some extra ciphering. The guys drew out it out actual size on the family room subfloor to figure out how it would work. I wonder if someday somebody will discover that drawing and figure out what it is.

For 125-some-odd-years these windows have not lined up, but now they finally will. It's a good thing.

It's so nice to finally see something (the new front porch) breaking the long flat plane along the front of the house.

Regarding the Jeld-Wen windows, I believe that they are going to hire a contractor to replace all of the window casings on site...but I haven't gotten the word officially yet. -- Bill

October 27, 2005

First off, hello to the guys from the framing crew who just found out about this Web site! See...I really have said nice things about you and your work!

I wanted to remove the window from the outside, while preserving it from the inside. Nice trick, eh? On the inside, the trim goes up into the ceiling and the wall, so pulling it all out would have made a big mess in a bathroom that we have to keep usable right now. Instead, we removed all of the outside trim and then cut off the sill flush with the studs so that it could all be covered with plywood.

We now have several ideas as to what to do with this from the inside. My favorite is to hang exterior raised panel shutters inside, to make it look like a closed window. Or we could use louvered shutters. If we did the latter we could even put a flourescent light box behind them so that you would see light coming from between the louvers. I hate flourescents, but maybe with the "daylight" tubes this could work.

The window opening on the left is brand new and will be in William's bathroom. The window opening on the right is an existing opening that was reframed. The plaster that was removed is between those two windows. I had already removed all the plaster in the area where the left window was to go.

We're in the home stretch with the carpenters. They should be done by Monday afternoon! The only things left on their list are to pull the siding in the back porch and sheath that area, put up the fascia and rake boards, and a few other odds and ends. Then it'll all be in my hands to finish up. An overwhelming, yet exciting prospect! (So to all of our friends and relatives who have been asking when they can come help...NOW would be good!)

The mason made some good progress on the master bedroom fireplace today.

That's the door to William's bedroom in the background. -- Bill

October 28, 2005

Fascia and rake boards and bed moulding are going up. Looks very nice. -- Bill

October 30, 2005

Saturday I built a prototype window for the reproduction sashes that we had made back in the spring. I used the existing dining room windows as my model. Today I started mass producing the components. There will be a total of twelve of these windows. Once I have all the parts and pieces produced, they will assemble very quickly. Several months ago I bought two Porter-Cable trim nail guns on sale. One is a brad nailer and the other is a finish nailer. Gotta wonder why I didn't buy these years ago; they sure will sure speed up projects like this.

Yikes! The glass is more than half empty! -- Bill |