ONLINE JOURNAL

These journal entries track our progress as we undertake our adventure of restoring this very old home. The main reason for keeping this journal on the web is that we have found that there are very few resources (books or websites) that follow all of the trials and tribulations of restoring an old home...from start to finish.

May 1, 2005

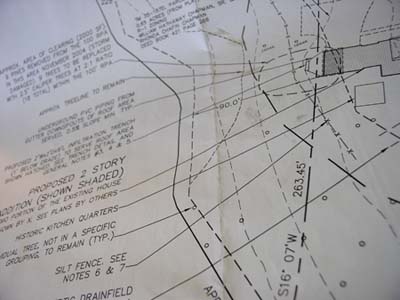

This file box is my constant companion. In it is every bit of information related to building the new addition...contracts, product brochures and spec sheets, photos, a tape measure, PDA with phone numbers and appointments, a piece of soapstone, and not one, but two checkbooks. Along with my blueprints, it gets thrown into my car at least once a day as I head out to do researching or pricing. I even have a color-coded file system. Green folders are for exterior items like siding, windows, roofing. Blue folders are for systems...HVAC, electrical, plumbing, etc. Yellow folders are interior details like kitchen cabinets, bath fixtures, and flooring. And so on. The system works pretty well. Portable and organized.

A long time ago I realized that Enon Hall has taught me patience, not a naturally occuring personality trait for me. Further evidence was that today I took about 60 clippings from the giant 100-year-old, 8-foot-tall English Boxwoods in the graveyard and established a small plot at the edge of the woods to try to root them. If this proves successful, in about 10 years we'll have some nice small boxwoods to use to create a formal garden somewhere. -- Bill

May 2, 2005

As of this morning, our deed of merger has been executed and recorded at the courthouse so that our site plan can be approved. With this done, I was able to submit our construction plans for a building permit. If all goes well, we should have our permit in-hand by the end of this week! -- Bill

May 3, 2005

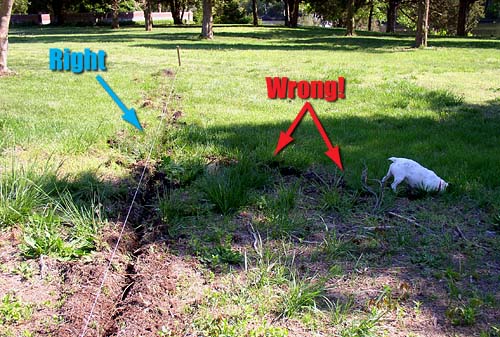

Good help is sooo hard to find.

It specifies everything we need to do to comply with the Chesapeake Bay Act and mitigate water run-off. One of those things is the installation of 160 feet of silt fence to remain up throughout construction. You have to dig a six-inch trench and then lay the cloth into the trench and backfill. The plans are VERY clear about where that fence needs to go. But does that matter?! Apparently not. No matter how many times I showed my assistant the plans...well, it just didn't seem to get through that hard head.

Oh well. Despite Lucy's help, I got about half of the silt fence installed.

Yup, it's a thing of beauty. -- Bill

May 5, 2005

Today's big accomplishment was knocking an item off of an ancient to-do list.

I had saved one of the old pieces (in pieces) and used it as a pattern to make two new ones.

Much better. Now we just need to trim the tops of those holly bushes.

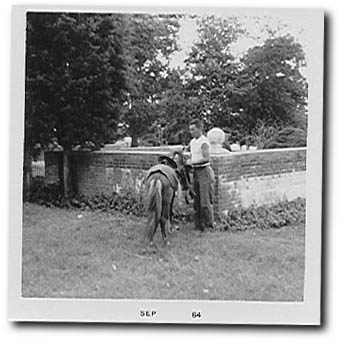

In the first picture you can see how the cedar tree has pushed the wall out of line. This got worse after Hurricane Isabel. Every time the wind blows hard, the cedar rocks against the wall.

Thanks to the McKessons for the 1964 photo! -- Bill

May 8, 2005

Mother's Day started with the roar of chainsaws as we had two more trees taken down to make way for construction and our new driveway.

One was a dead cedar (left) and the other a large and very gnarly pine (right).

They were down and hauled away in short order. May 9, 2005

Gay rounded up the tie-dye t-shirt and overalls. William supplied the head. My sole contribution was observing that this year's scarecrow is undoubtedly...well...a pothead. An angry pothead, in fact.

Our beautiful red maple really stands out now that the gnarly old pine is gone. The pine was to its left. -- Bill

May 10, 2005

I called the County this morning to follow up on my building permit application and was told that it hadn't even been started because the site plan still hadn't been signed off on! I thought that was done last Monday when I dropped off the Deed of Merger! The Land Use guy had told me that that was all he needed to give his blessing to our site plan, so I wrongly assumed that he was headed back to his office right then to wrap things up. I even asked him as he walked away..."So, I'm good to go ahead and get the building permit application going?" and he responded that I was. But when I talked to him this morning he said he hadn't even started his "review" yet, but I was "near the top of the stack." It's so frustrating...but what can you do? I have to continue to be nice, or that stack will surely grow taller on top of our plan. Plus, he's like 6-foot-8.

And that's just what I pulled out with my bare hands. I dug it out further with various implements of destruction until I had hit solid and dry wood in all directions. I decided to give my friend SculpWood a shot at this job. It would take a lot of the filler, but if it worked, it would still be cheaper and a whole lot more practical than replacing the whole sill.

I'll let it cure overnight and then sand and prime it tomorrow. May 11, 2005

The wildflower field that we planted last year is starting to come alive as the perennials come into bloom. A few here and there...hopefully many more on the way. Meanwhile, the buttercups are going crazy this year. May 16, 2005

Scraping and sanding window sashes doesn't make for very exciting Web site updates. Today I got one 9-pane sash ready to prime. May 17, 2005

Speaking of windows...the new Jeld-Wen windows arrived this morning. These windows will go in areas of the addition that we aren't trying to make look old-old...like the kitchen, colonnade and garage. I got the Williamsburg trim package and the enlarged sill, which will make them a pretty good match to the other "old" windows in the addition. I had to order these windows when I did because Jeld-Wen rolled out a 30% price increase on April 1st on this Norco line with their new AuraLast wood treatment. Auralast is their new award-winning wood treatment process that is supposed to make the windows termite, water, and decay resistant.

After six years wondering what was going on under there, this morning I removed the Band-Aid and found that the damage was bad...but really not as bad as I was expecting.

Yep...another job for SculpWood. (Good thing I just re-stocked!) First, I scraped and sanded everything as best I could and removed gobs of old caulk. I left the old nails in place. I like having them there for the Sculpwood to wrap around and adhere to.

You can see that the problem is not just the rotted-away sill end, but also that the entire surface of the window sill is badly checked. If left like this, water could easily seep back in and start the damage all over again. So the job was to re-create the missing end, and also fill in all of that checking.

After the RotFix step, I applied the SculpWood with my hands, working it into a crude rounded shape at the end and working it into the checking on the surface. In a few hours when the first pass had cured, I sanded it all down and worked in a little more Sculpwood where needed.

There are still a few places to fine tune tomorrow, but it's looking pretty good.

One down, nine to go! May 18, 2005

This morning I got the bright idea to use one of the sets of replicated sashes to fill the gaping window hole while I'm working on the old sashes. Three hours later, I realize why Mr. Hayden never put these sashes in place. I knew this window was out of square, but just how much quickly became apparent when I tried to put the square sashes in it.

The old square peg in the parallelogram hole test...

Picked up the building permit this morning, first thing. It's real! -- Bill

May 22, 2005

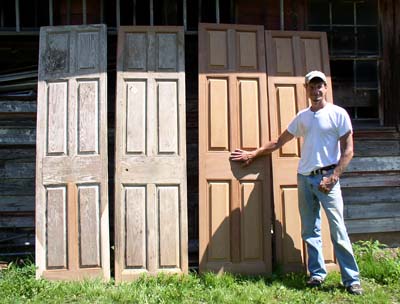

On Saturday we went up to Maryland to pick up our Amish-made window sashes and doors. 24 sashes and two sets of double doors.

We're very happy with the job that he did replicating the old window sash that we took him. He is primarily a furniture maker and his wood of choice is mahogany so that's what he used for our sashes. They should last forever, but it will sure be a shame to paint them. I got him to leave the bottom rail long so that I can cut them down on site.

He also did a beautiful job repairing the double doors that we found in the chicken house and made us a beautiful matching set. It will be wonderful to be able to open up these doors at both ends of our new hall and let the breeze blow through from the creek. May 23, 2005

I'm introducing a new site feature will make Gay very nervous. But, in an effort to make this site as informative I've possible, I've decided to add a budget tracker that will appear periodically in our journal updates. The budget tracker will indicate where we are at the moment...expenses against total budget for the addition.

Again, considering that we have yet to break ground, the current 18% percentage is a little out of whack because it includes a number of items that we have already paid for in full like windows, doors, and bricks; plus a sizable deposit on our kitchen cabinets. May 26, 2005

Wow, I am impressed. I ordered the restoration window glass on Monday and received it today. They had said to allow 2 to 3 weeks for delivery so this was a pleasant surprise. The new glass doesn't have as much distortion and rippling as my old panes, but it looks pretty good. And it's a full 1/8th inch thick, so it should be much less prone to breaking and cracking than the old, very thin panes. I will re-use as many of the old panes as possible and mix in this new glass where needed. -- Bill

May 30, 2005

The word from the mason is that he is planning to be here this Thursday or Friday to start digging the new footing! -- Bill

May 31, 2005

In anticipation of the arrival of the mason, today's job was to have been the removal of one corner of the 1850s foundation. Years ago, the corner had fallen away and the opinion of the builder and the mason was that the corner could be safely removed because there didn't seem to be any weight sitting on it. (They decided this after easily sliding putty knives in and out between the brick and the sill from the front.) So, the plan was for me to remove the corner so that I could clean up the old brick for re-use. Then a footing would be poured under the corner for the rebuilt foundation to sit on. I was armed with a cold chisel, brick hammer and a jack and blocks for stablizing the corner once the brick was out until the mason arrives.

But upon removal of the bottom two siding boards on the gable end of the house, it was easy to see that the corner was making contact with the bricks after all. So that immediately ended my participation in this project. I called Kenny (the builder) and he was here in fifteen minutes to take a look. "Yeah, let Doug (the mason) pull it."

On the gable end the framing was filled with ancient mouse nests and all of things they dragged into them. I cleaned it all out into a bucket for William to sift through later for treasures. I found a few items myself, including some broken ceramics, a thimble, an old key, a wooden curtain rod (maybe?), tons of old newspaper with Civil War era typefaces, and a tiny, primitive rag doll. |